“PC-1203 Perry Class”

Measurements:

Measurements:

- Length: 77 cm

- Displacement: 7.700/8.00 KG

- Scale: none

This is a “re-building” thread, as the model was given to me as a “RTRish” gift on Christmas 2016.

Work began: 25.12.2016

Maiden voyage: 22.05.2017

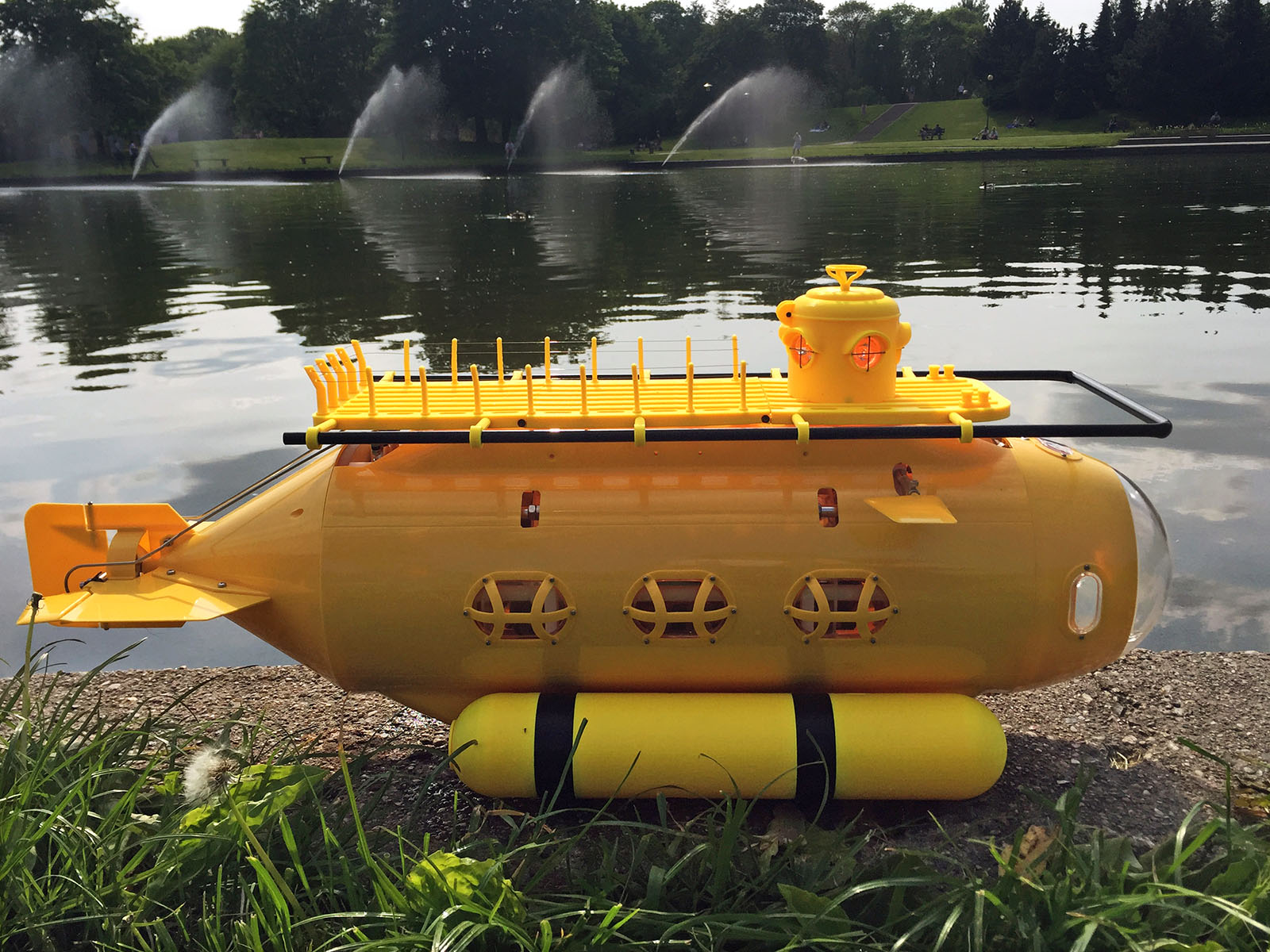

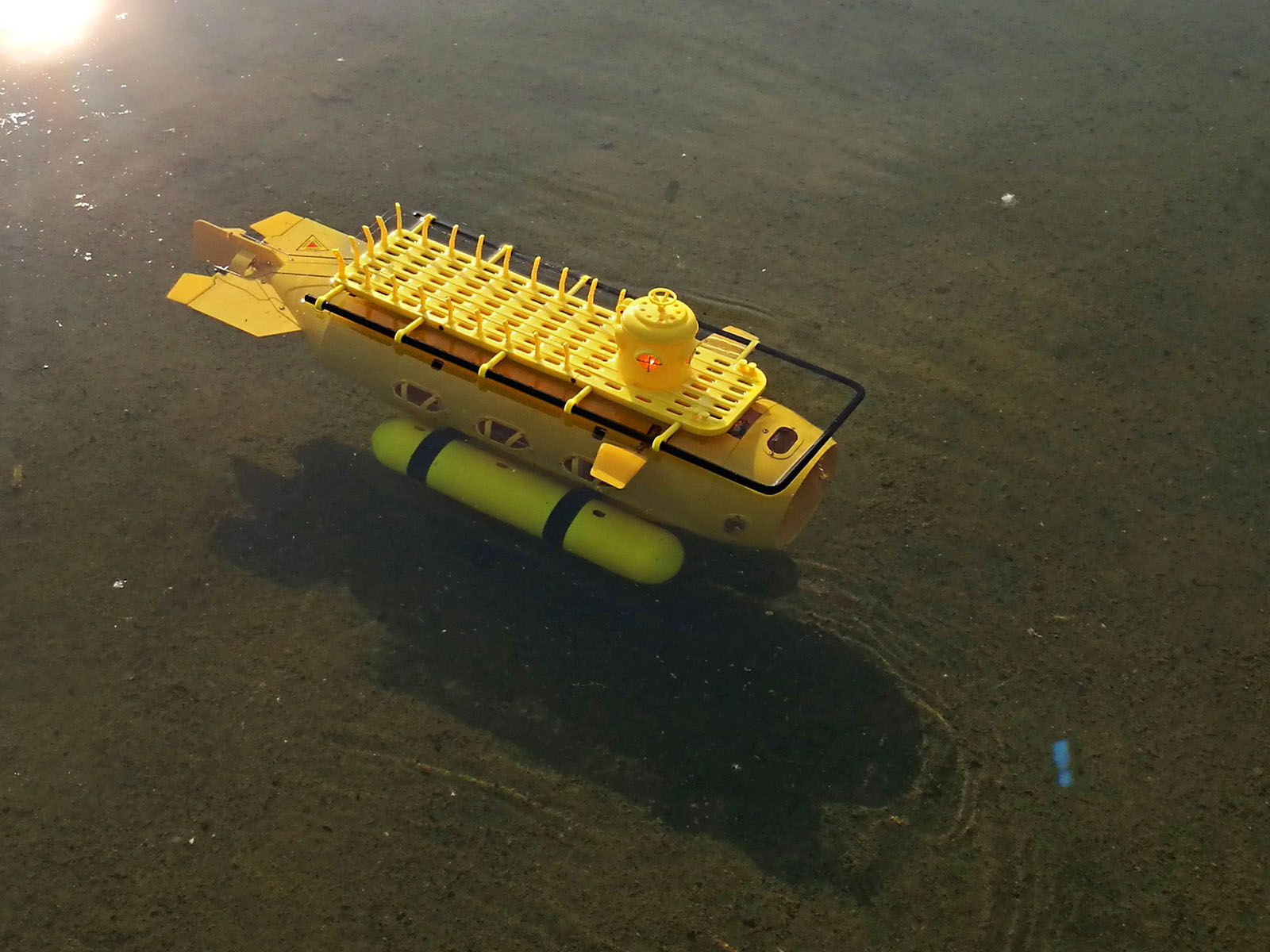

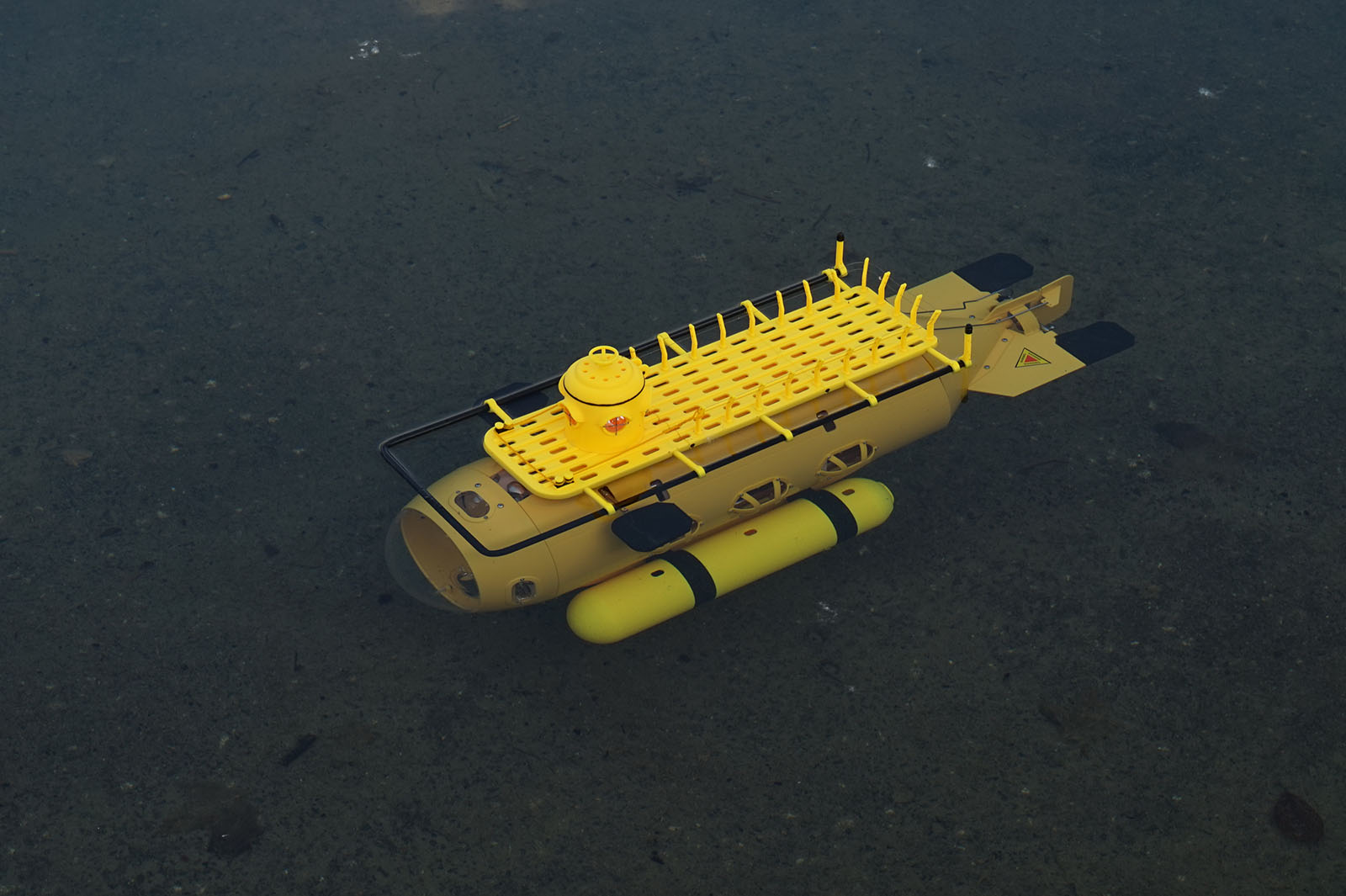

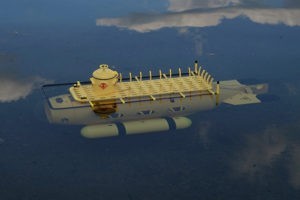

My PC-1203 – Perry class is nothing more then a modified Neptune SB1. It’s a rather old RTR set which was produced within a short period by Thunder Tiger, during years 2008-2009. The model was not very popular cause of two reasons:

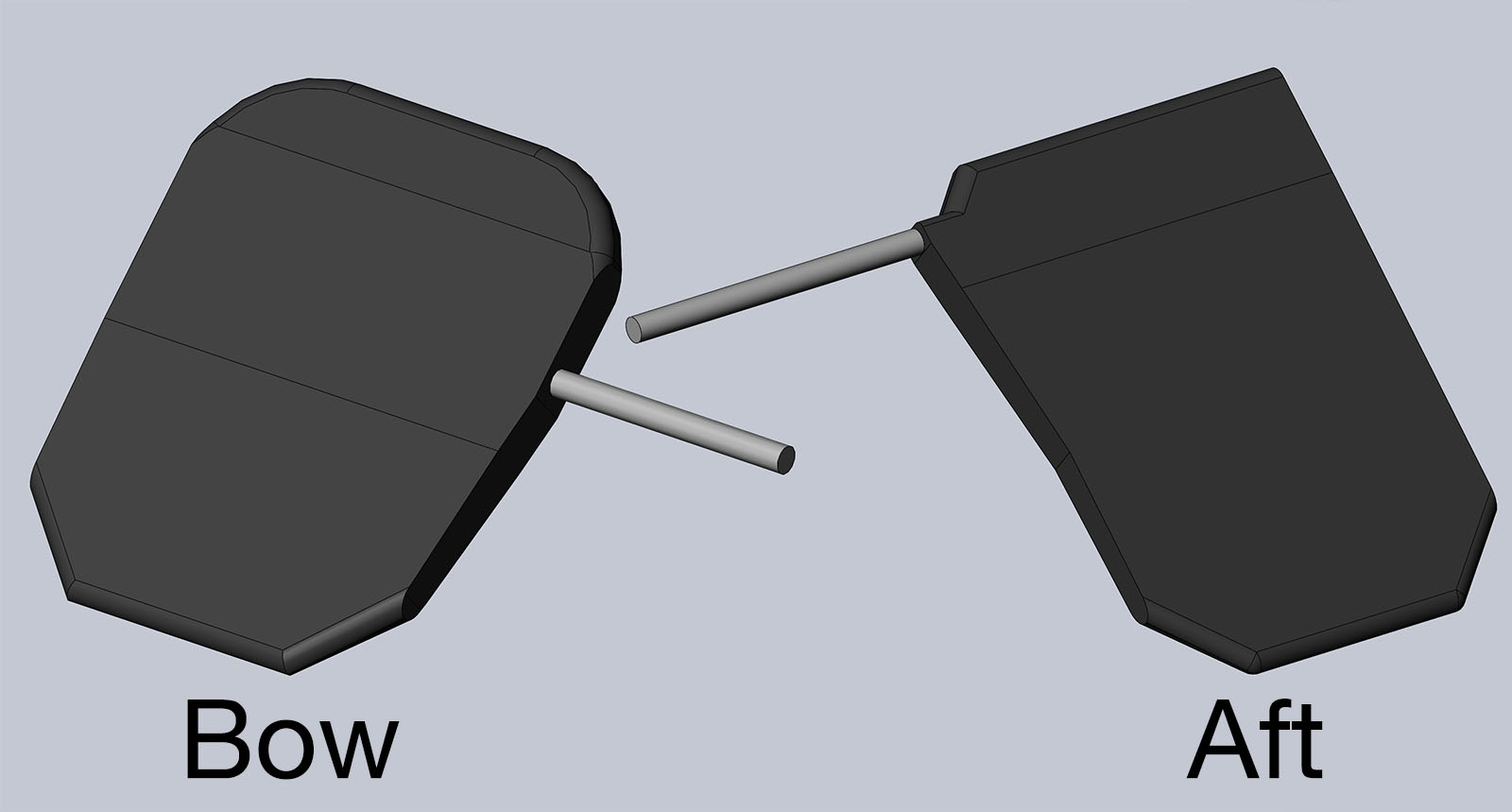

Reason one was that it had few “childhood diseases” and quality control issues. Many of the units were leaking – not something particularly good for a RTR submersible… Most of them had leaks on the shafts main gasket – due of not enough lube on it and premature wear off. There were also problems with the model being was lubberly when it came to depth change. The dive planes were simply to small. Those two problems were extremely simple to fix by every model maker, but as it was an RTR – not something model makers buy… This leads us to the second reason of the lack of success of this product.

The second reason is a bit more complicated – we can call it a “socially-economic” problem. Despite of being equipped with advanced mechanisms like the static diving system based on a elastic diving tank with digital pressure control, the model was to much ‘toy looking like’ for the serious model makers – RTR is not something you can work on, right? On the other side you had people who were not model makers and they wanted to get this thing as a cool gadget, but they weren’t exactly willing to pay 500$ for something they’ll use few times a year. It was the time before all the drones and RC toys became trendy.

The second reason is a bit more complicated – we can call it a “socially-economic” problem. Despite of being equipped with advanced mechanisms like the static diving system based on a elastic diving tank with digital pressure control, the model was to much ‘toy looking like’ for the serious model makers – RTR is not something you can work on, right? On the other side you had people who were not model makers and they wanted to get this thing as a cool gadget, but they weren’t exactly willing to pay 500$ for something they’ll use few times a year. It was the time before all the drones and RC toys became trendy.

I got mine from a local store in Poland and as I said earlier, it was given to me as a gift – from my Wife. The seller told her that the model was on the shelf for 8 years. I knew this might cause problems as rubber gets old and I was not mistaken… I’ve decided to make a full check-up and service before the first run.

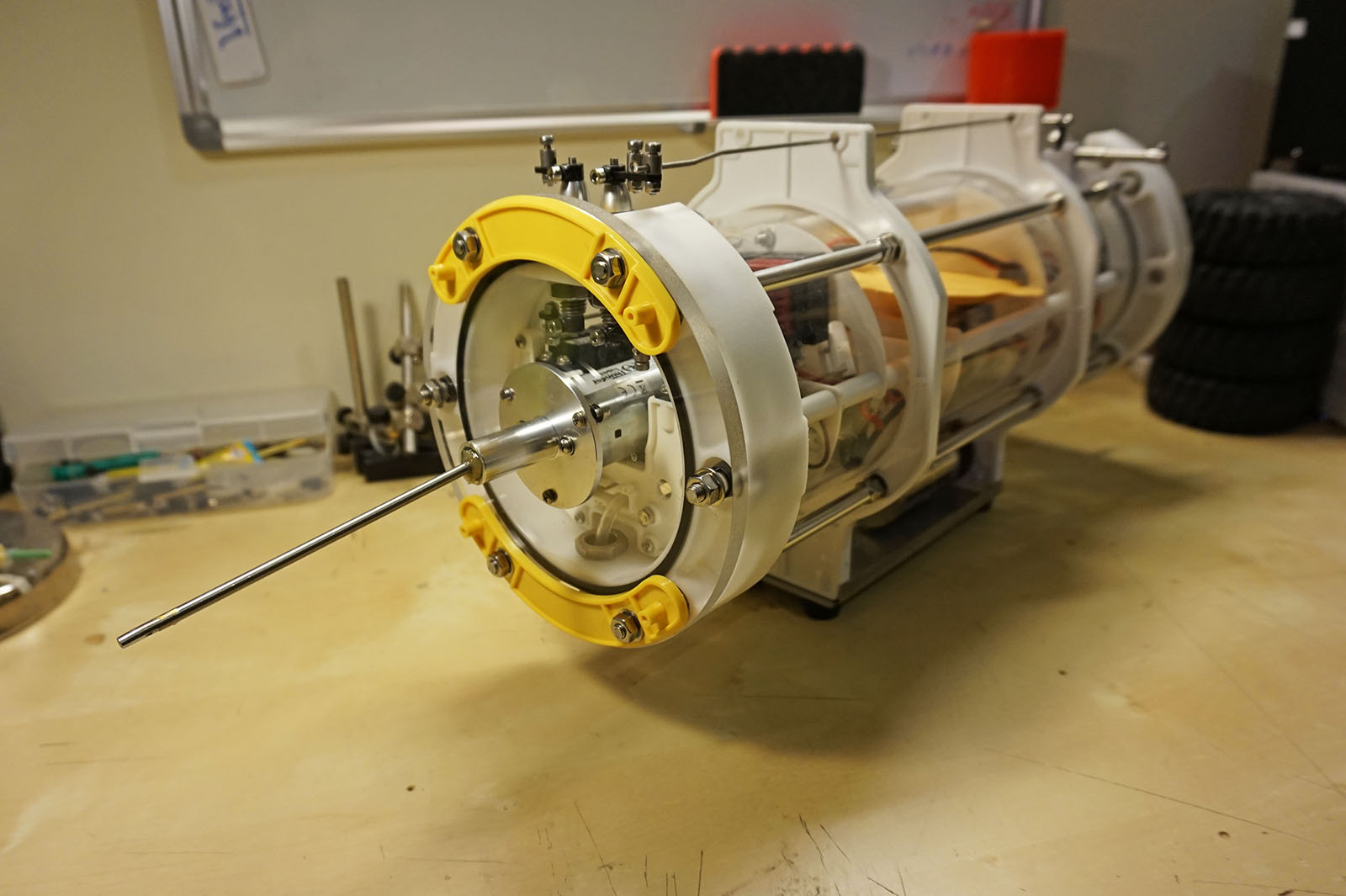

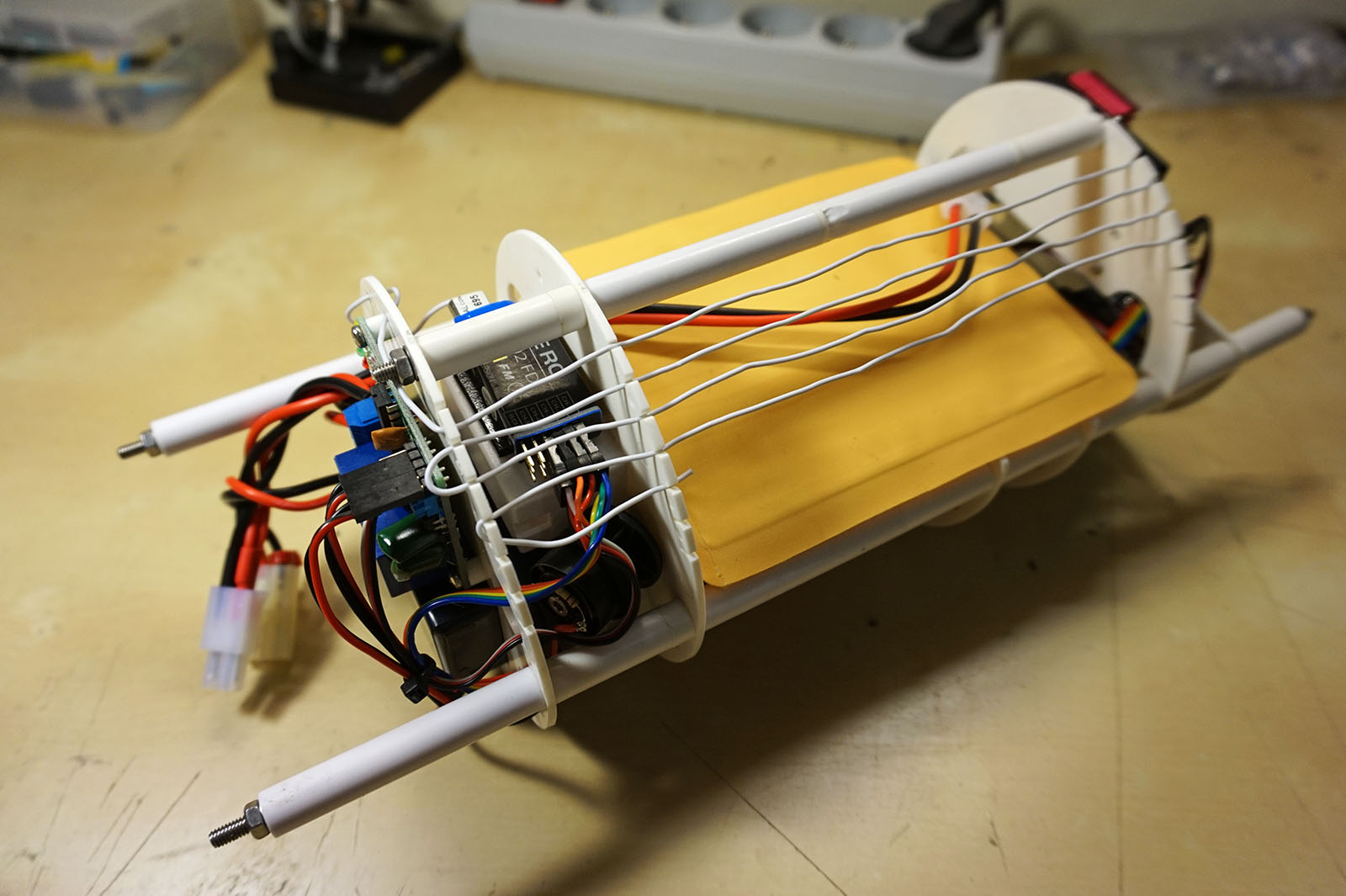

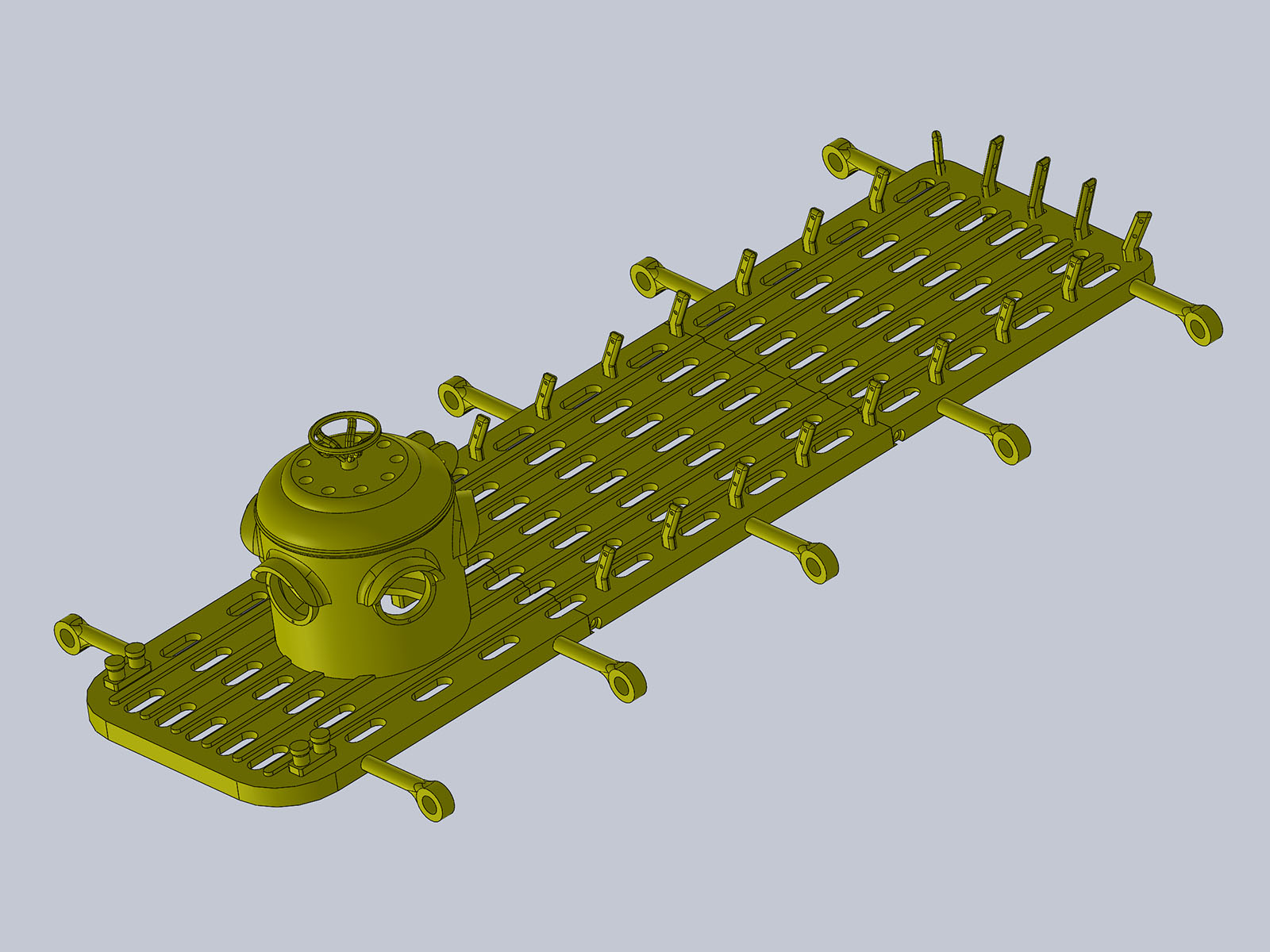

Removing all the yellow elements is very easy. They only give the model it’s hydrodynamic shape, it’s the free flooded part of the hull.

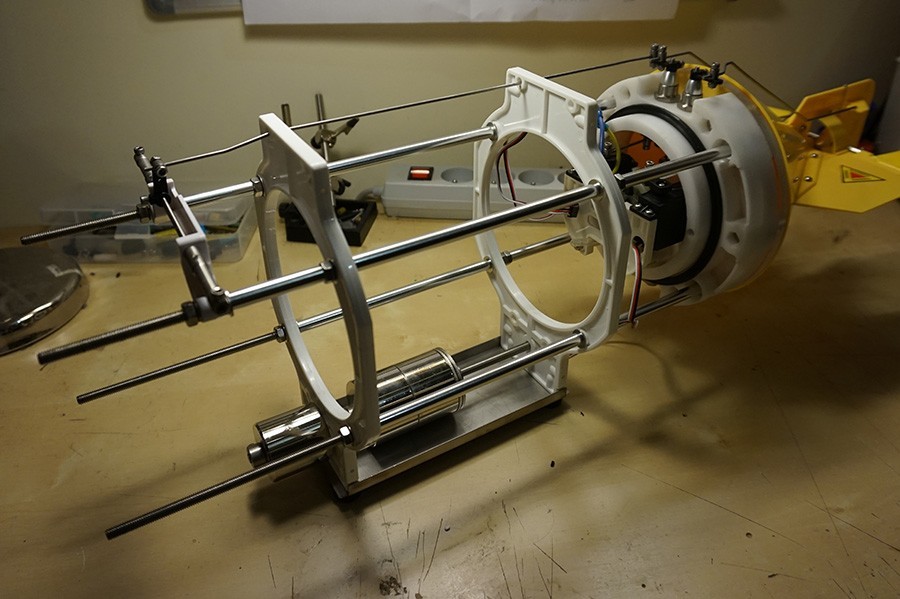

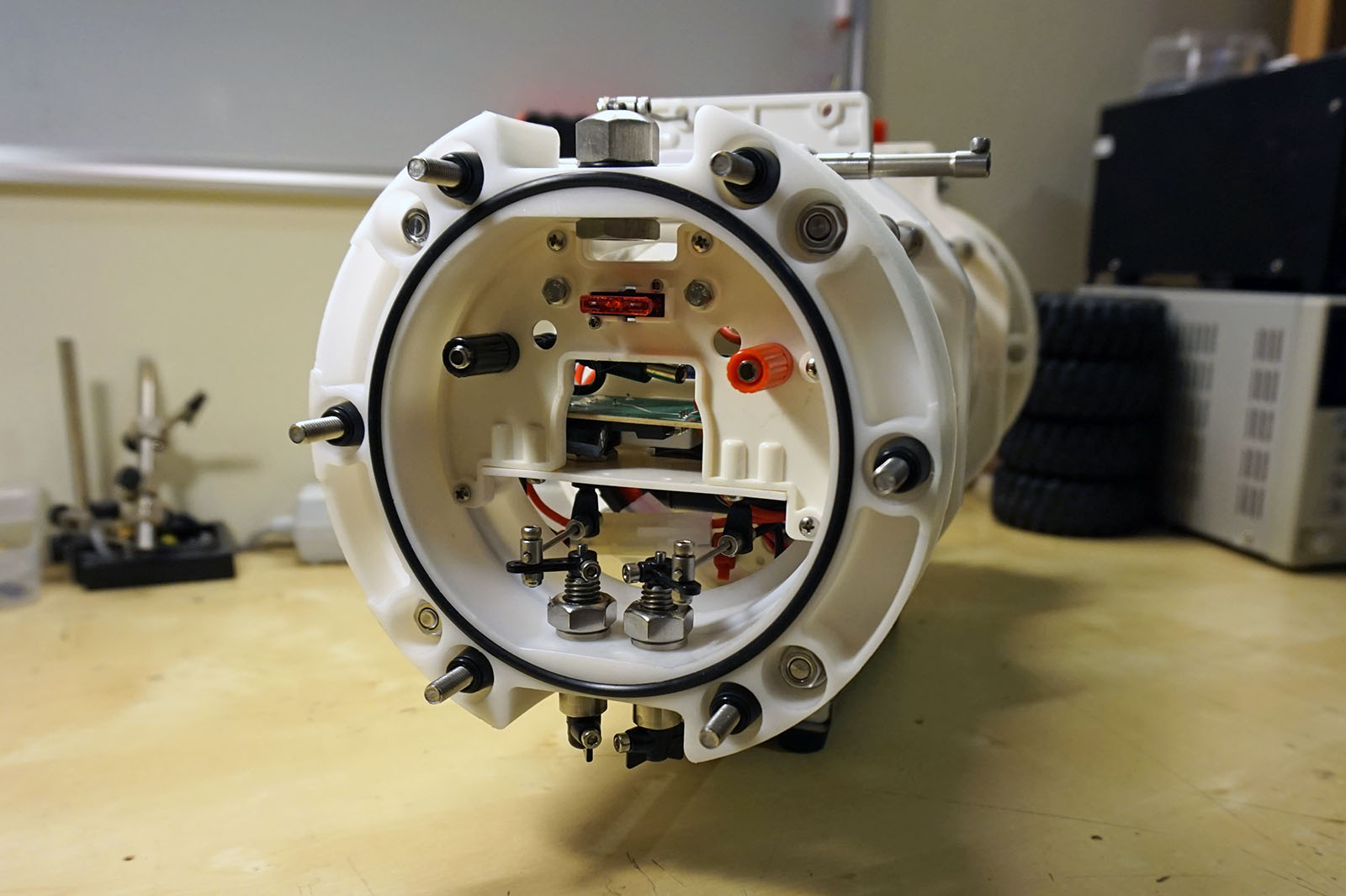

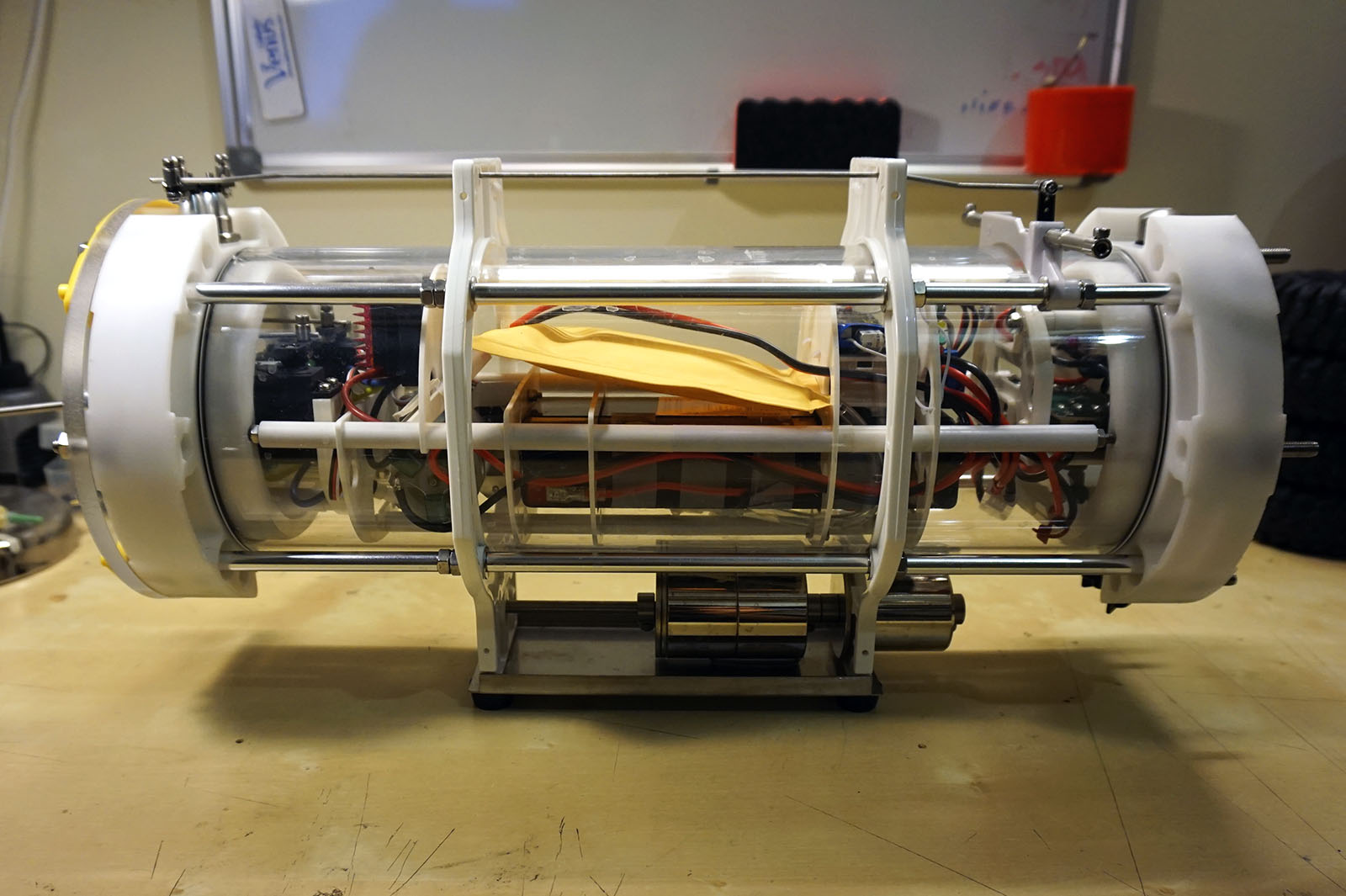

The dry hull – WTC is well designed and manufactured with a really decent quality, but assembled in a very lousy manner… As I wanted to gain access to EVERY seal and gasket for a visual check, I had to dissemble the model completely – to the bare bone.

So from RTR it quickly became almost a KIT 🙂

The high quality of the parts is clearly visible with each removed element. All the metal parts are properly machined with a high polish finish, the plastics are stiff and hard. The main support element consists out of 4 stainless steel threaded rods additionally stiffen and protected by aluminium sleeves.

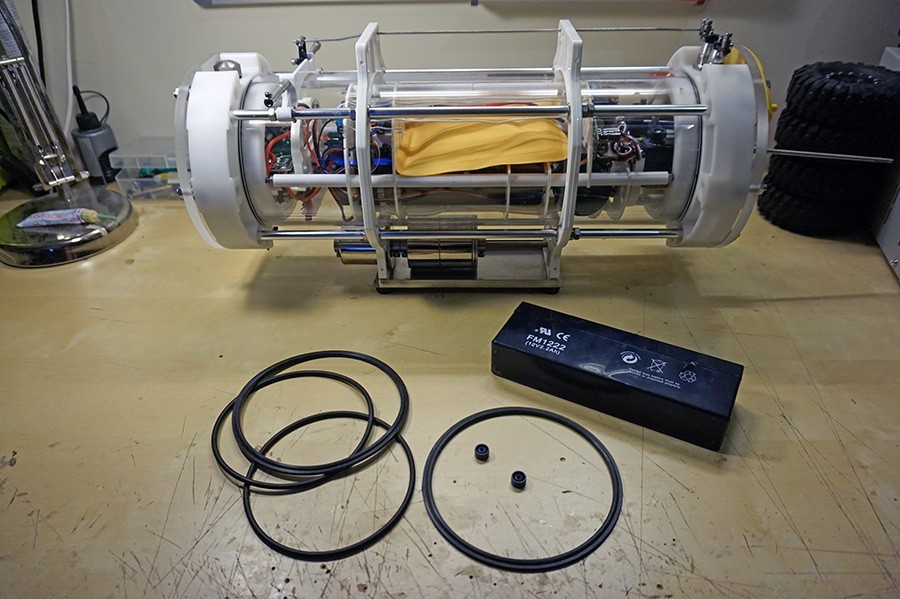

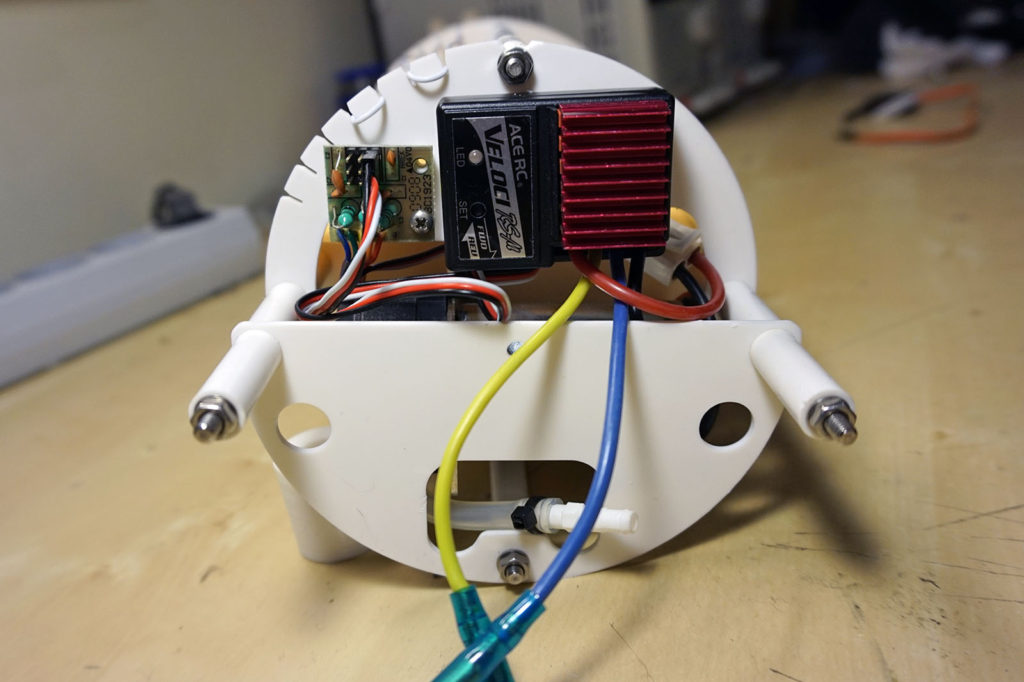

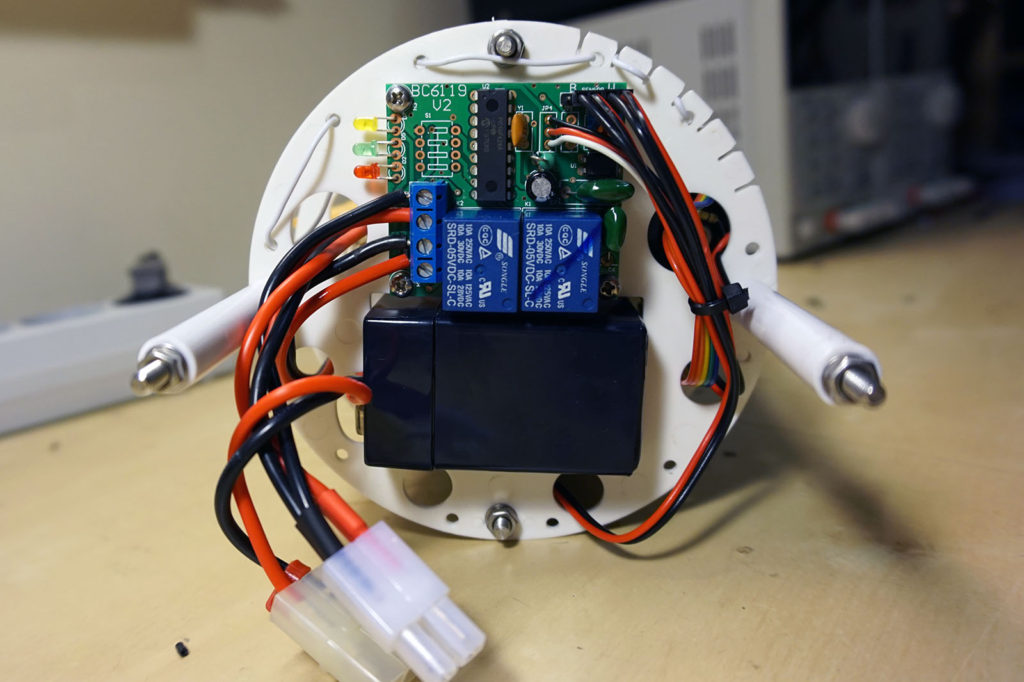

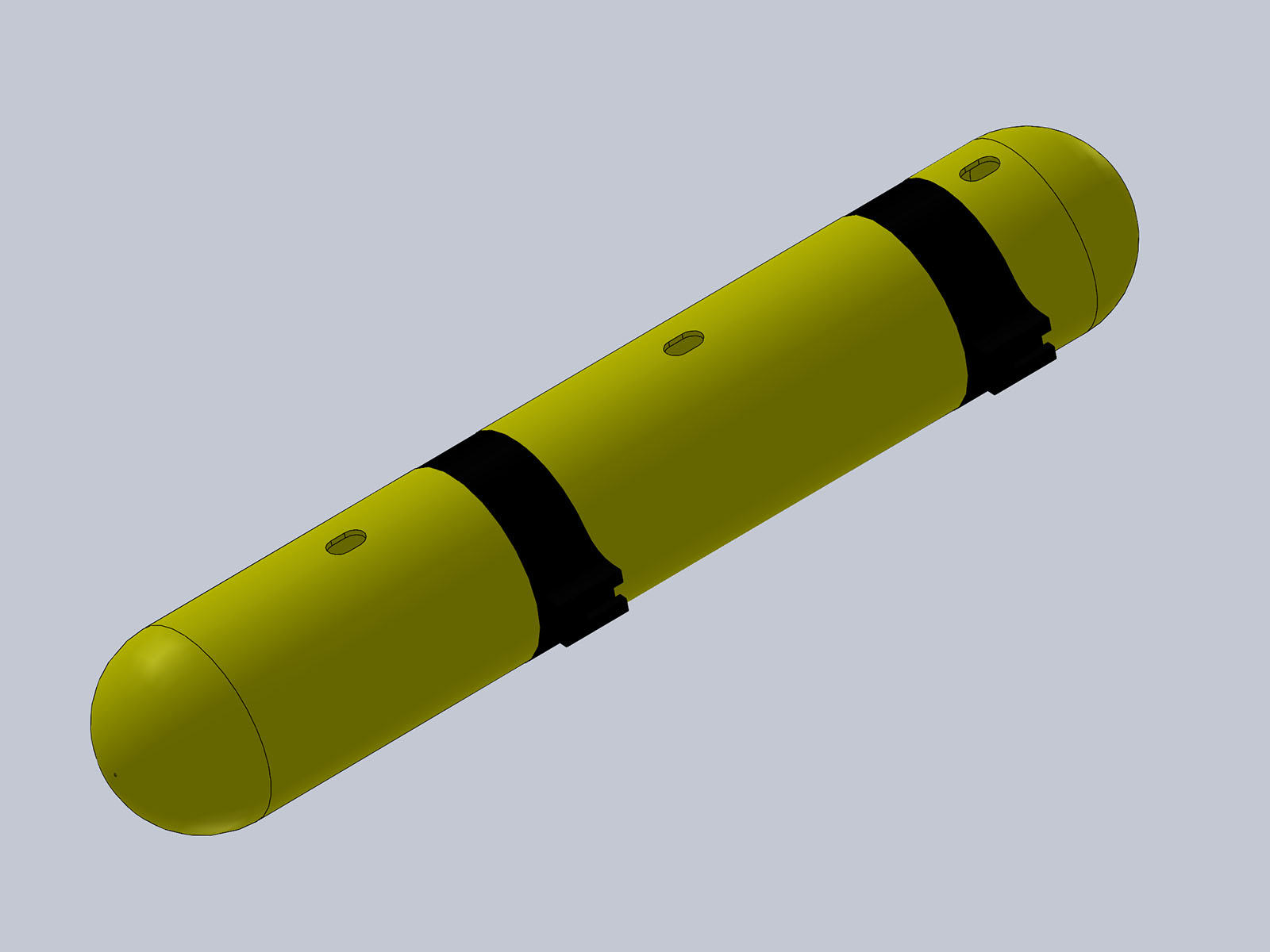

Model is a static diver, which means that it has a diving system. It has and elastic water tank (bladder) and a peristaltic pump so it doesn’t require any additional valves or air tubes. Additionally the system has been equipped with a pressure sensor which will keep the elastic tank from ripping due to overflow. Everything is controlled by a microprocessor with two relays and leds. The LEDs inform the user about battery level and the currently receiving command form the RX (dive/stop/surface). It’s a very good idea as the driver will not allow for a dive, if the battery level is too low. The driver has also a port for additional flooding sensor, but the sensor itself was not included with my unit.

Things which needed immediate replacement:

- Perished Seals of the tubes WTC.

- Simmerings of the dive planes and rudders servo pushrods – both damaged/perished.

- Seal from the Video Cable socket. Some moron caught the seal in the thread while screwing the nut on.

- 12V battery was dead, not capable of charging above 8V

- Main shaft seal not lubed enough, but in surprisingly good condition.